Misc Specialty

Miscellaneous Specialty

If you don’t see what you need, please contact us.

We can find it for you.

We can find it for you.

Services Beyond Parts

Purchasing and Sourcing

Purchasing and Sourcing

Find the right part, material from our huge global network of resources.

Learn More Solutions and Capabilities

Solutions and Capabilities

Need help solving a problem, prototyping a solution or some other specialized skills.

Learn More Engineering Solutions

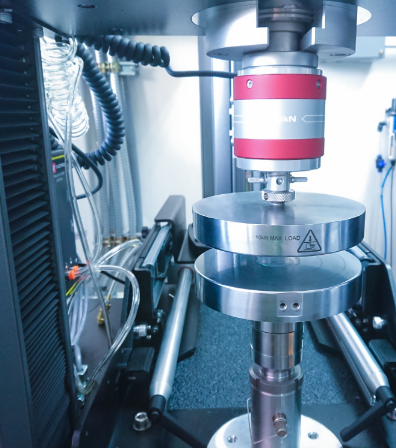

Engineering Solutions

Reverse engineering, 3D modeling, testing and part improvement expertise.

Learn More Wholesale Accounts

Wholesale Accounts

Leverage buying power, gain industry insight and stay connected at a large scale.

Learn More

“More than just a parts website. The account manager helped us plan ahead with inventory so we could avoid disruptions with our production schedule. Their engineering resources were available to assist with our application requirements. Highly recommend this team!” — Satisified Customer

CAN'T FIND THE PART YOU NEED?

Shoot us an email or call (503) 802-1370